High Speed Tensile and Dart Penetration Testing

High Speed Tensile Testing

In addition to performing standard Charpy and Izod impact tests, our laboratory is equipped to conduct high-speed tensile and dart penetration testing using the Zwick Rel 1852 hydraulic test machine. This equipment supports test velocities of up to approximately 12 meters per second, enabling simulation of real-world dynamic loading conditions encountered in automotive, aerospace, and packaging application

Using high-speed video capture and post-processed video extensometry, allows precise measurement of strain rates and deformation profiles. This setup is particularly effective for generating dynamic stress-strain curves, which are essential for accurate finite element analysis (FEA) in impact modelling and crash simulation studies.

The Zwick 1852 incorporates a liquid nitrogen-cooled environmental chamber, enabling controlled testing across a wide temperature range—including room temperature, elevated thermal conditions, and sub-ambient cryogenic environments. This flexibility supports material characterization under diverse service conditions.

When operated in

tensile mode, the system complies with industry standards, including the

Volkswagen TL669 specification for high-speed deformation testing of fuel tank materials. TL669 explicitly mandates the use of a Zwick 1852 machine, ensuring that our testing protocols align with OEM requirements.

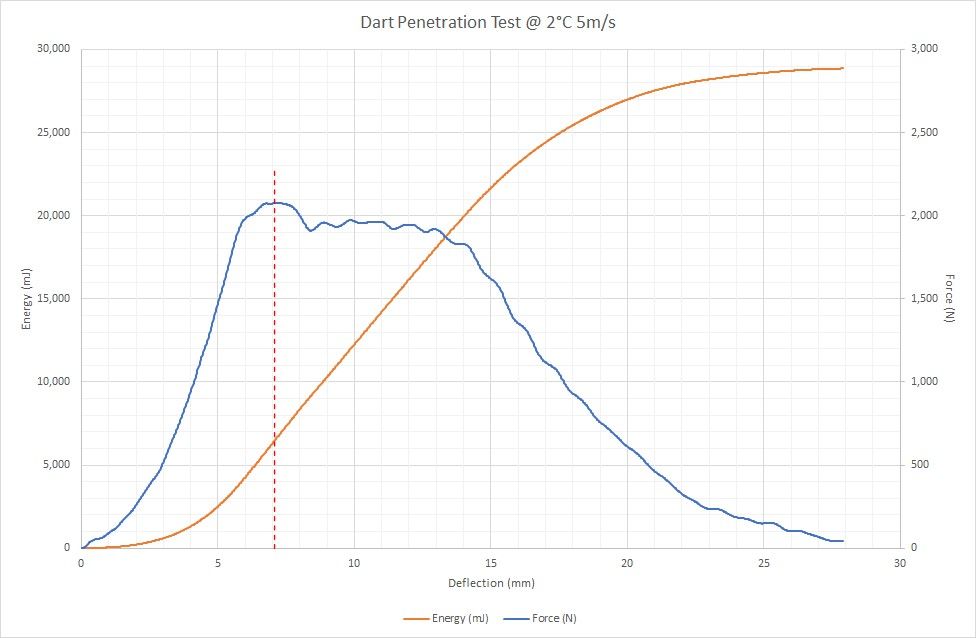

Dart Penetration Testing to ISO Standards

Our Zwick REL 1852 high-speed hydraulic test machine is equipped with specialized dart penetration fixtures, enabling testing to key international standards for impact resistance testing of polymers and films. Specifically, we support:

- ISO 6603-2 – Determination of puncture impact behaviour of rigid plastics: This method evaluates the energy absorption and failure characteristics of rigid polymer materials under dynamic puncture conditions.

- ISO 7765-2 – Plastic film and sheeting – Determination of impact resistance by free-falling dart method – Instrumented puncture test: This standard assesses the toughness and puncture resistance of flexible plastic films using a falling dart impact setup.

Both standards specify a nominal test speed of 4.4 m/s, equivalent to a 1-meter free fall, to simulate real-world impact scenarios. However, our advanced setup allows for variable test speeds up to 12 m/s, providing enhanced capability to characterize strain rate sensitivity and dynamic deformation behaviour across a wide range of polymer types and thicknesses.

This flexibility is particularly valuable for automotive, packaging, and aerospace applications, where materials are subjected to high-speed impacts and require precise modelling for finite element analysis (FEA) and product validation.